To what extent can ozone remove geosmin in RAS?

Ozone in RAS

In land-based recirculating aquaculture systems (RAS), fish are farmed in reused water. Good water quality is vital in such systems to support growth, minimize disease outbreaks and ensure the welfare of the aquatic organisms. Ozone is an excellent candidate to improve water quality by oxidizing natural organic matter, removing color and suspended solids, accelerating protein degradation, improving coagulation and filtration processes, enriching the water with oxygen, removing off-flavor compounds (geosmin and 2-methylisoborneol (MIB)), and therefore improving the taste of fish. It is also able to control the microbial load resulting in improved growth.

If ozone is not properly used, it can adversely affect both human and aquatic organisms. Ozone is toxic at residual concentrations (0.01 - 0.1 mg/L) as it oxidizes the gills and the surface mucus layer of the fish eventually leading to death or making the fish susceptible to microbial infections. Depending on the water matrix, detrimental by-products might be formed, such as bromine (LC50 of 0.068 mg/l BrO- in rainbow trout), bromite and bromamines, which are toxic to fish, bivalves and crustaceans while bromoform (bioaccumulates in aquatic animals) and bromate are potential human carcinogens.

We know all about ozone

Over the years, we have gained deep knowledge in dissolving ozone gas optimally into the water, ensuring maximum treatment efficiency and minimum cost and operational risks. Ozone is an unstable molecule and expensive to produce. The ozone lifetime is very short and highly affected by temperature. The length of the tubing used to transfer ozone should be kept as short as possible to minimize ozone destruction within the residence time in the inlet tubing. Thus, it must be produced on-site, next to the dissolution point. Several advantages are stemming from this decentralized use:

- Maximum dissolution efficiency

- Minimum losses

- Increased safety

- Minimum risks of leaks

- Low installation cost (fewer parts, shorter tubes)

- Maximum water treatment efficiency - even if one of the ozone generators stops working, most water will be treated

OxyGuard Group has developed a reliable and safe ozone generator with stable output, which is easy to work with. The Gaia Ozone Generator is based on a unique and patented technology by Water ApS. It produces steadily high ozone concentrations (8-15% wt/wt) with the lowest possible energy consumption.

Another significant issue is to measure and continually monitor the ozone to avoid under or overdosing. OxyGuard International A/S has developed a very sensitive ozone sensor specially designed for aquaculture, which measures the partial pressure of the ozone directly in the water. The sensor is exceptionally stable and has an extremely fast response time. The detection limit of the probe is down to a few ppb.

An OxyGuard Pacific Control Unit, which receives data from the ozone sensors monitors and controls the ozonation process. The Pacific can be programmed to have specific set-points, and in case of any ozone excess in the treated water flow, the ozone sensors will give a signal to the control unit, which will immediately stop the ozonation, securing that no residual ozone will reach the fish tanks. The amount of ozone required is system-specific and highly dependent on the ozone demand (ozone reacts rapidly with the easily degradable compounds, resulting in an immediate ozone consumption), which depends on the amount of feed added, feed utilization, water treatment, the degree of dilution, etc. The ozone dosage will be adjusted according to the water quality requirements of the specific system. This automatic adjustment of the ozonation will save energy and keep running costs for the entire ozonation system low, ensuring safety.

Cobália is an advanced aquaculture management platform (OxyGuard International A/S.), which can control and evaluate every part of an aquatic animal production system. The farm management system will a) collect data measured by various sensors, b) give alarms or automatically adjust parameters deviating from given set-points, c) plan and monitor tasks to be performed by the staff, d) compare actual growth, feed consumption, mortality and other important parameters to standards and benchmark against earlier achieved results, e) keep track of inventory and maintenance need, f) auto-generate reports for authorities, g) and give a complete visual overview of the conditions on the farm. With Cobália we ensure complete documentation and traceability from egg to harvest and from farm to fork.

Our experience with the removal of off-flavor compounds by ozone

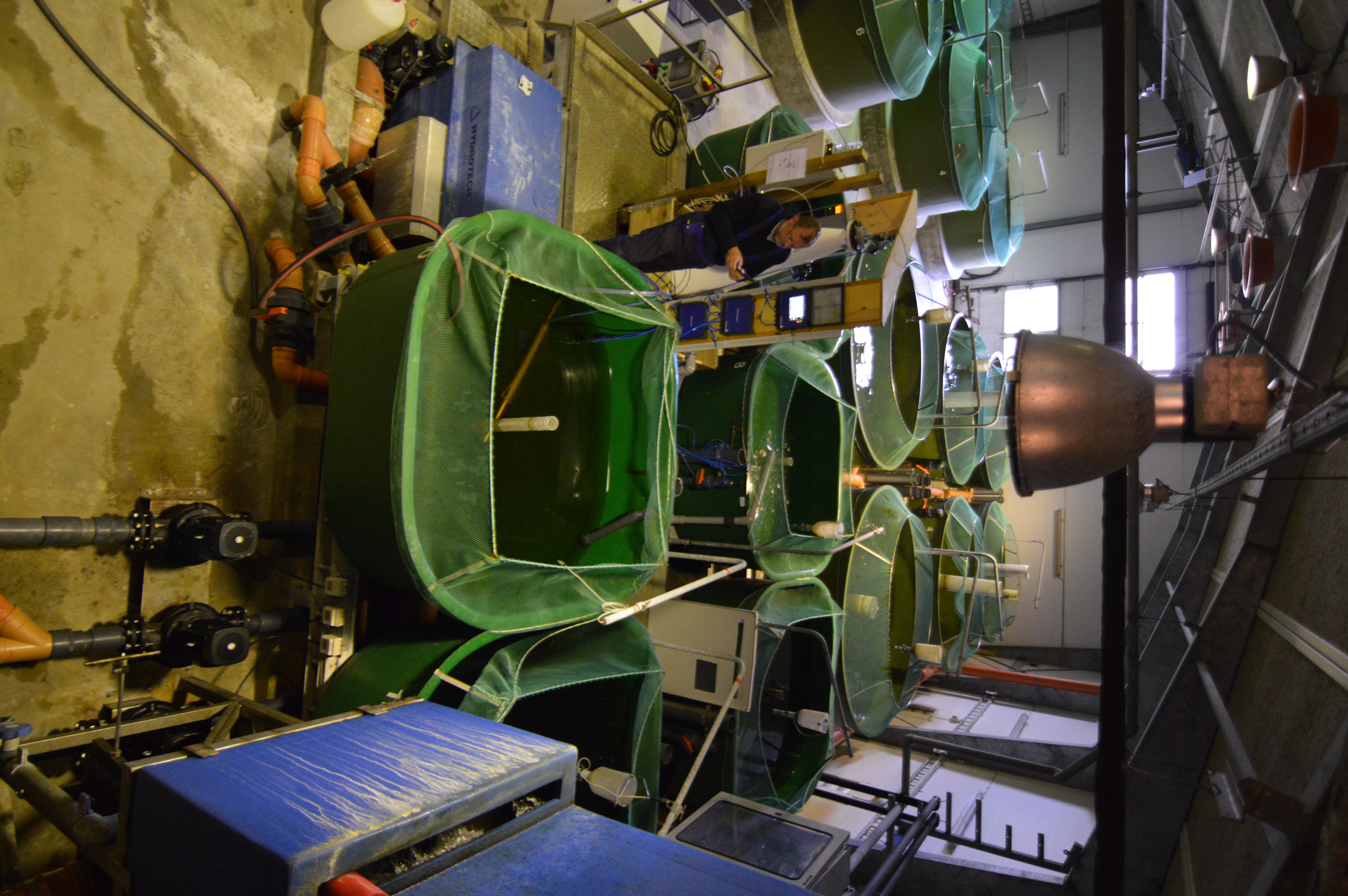

Although purging is a common practice to remove off-flavor compounds from fish flesh, it has a significant environmental impact resulting in reduced revenue. To address the issue of off-flavor compounds in RAS, which are responsible for the muddy taste and odor of fish, OxyGuard Group participated in the VIDA project (funded by the program "Value-added innovation in food chains" and supported by the EU program INNOSUP), where ozone was integrated into a commercial RAS. The ozonation was followed by a small UV system to enhance hydroxyl radical formation (Advanced Oxidation Process; AOP) and to destruct the residual ozone converting it to oxygen. Ozone sensors were used to continually measure potential residual ozone and control the ozone treatment.

A remarkable improvement in the color due to the oxidation of humic substances was observed just after a few hours. After three days, the whole water volume in the freshwater RAS department was transparent. Although the initial geosmin content was low (~5ng/L), ozonation achieved a 60% geosmin removal in 3 days while the bacterial activity (determined by BactiQuant™, Mycometer) was reduced by 25% during the same period .

Bacteria are important for the optimal operation (e.g. biofilters). We did not intend to disinfect the system; therefore, just a reduction was expected. The fish behaved as expected and welfare was improved (subjective evaluation based on watching the swimming activity and comparing to fish in untreated muddy water). The fish remained in the treated water for a couple of days and showed no sign of failure to thrive - they also started feed intake after the first night 'in the new environment.' The ozone sensors regulated the amount of ozone that was injected into the system to avoid overdosing. This demonstrates the value of the newly developed highly sensitive ozone sensors and the ability of the system set up to manage the whole process.

This short-term study provided some encouraging result regarding ozonation in RAS and its effect on the water quality as the organic matter as geosmin was removed from the water without compromising fish welfare. However, additional research is needed to test the concept for a longer period in systems with higher geosmin contents. The expertise and novel equipment developed by OxyGuard Group seems to significantly improve water quality and aquatic animal welfare in RAS.