Are we closer to an answer on the

off-flavour challenge in RAS?

Can the use of ozone eliminate enough geosmin and MIB to remove the need for the expensive and time-consuming purging in RAS?

Ozone is a powerful reducing agent that effectively targets organic matter, viruses, bacteria and parasites. Since the beginning of the last century, ozone has been used to purify municipal wastewater. Following, it has been introduced as water treatment in aquariums, swimming pools, drinking water, industrial process water and also water used in fish farming.

Recirculation Aquaculture Systems (RAS) are land-based systems where fish are farmed in reused water. The water in these intensive production systems is heavily loaded by organic matter which allows microorganisms to proliferate. Some of these microorganisms produce small molecules such as geosmin and 2-methylisoborneol (MIB), which may introduce an undesirable muddy or musty flavour in the fish.

Even extremely small amounts of these off-flavor compounds (OFCs) lead to a muddy taste in the fish, making it unmarketable for human consumption. The common practice to deal with OFCs is purging the fish in clean water, while depriving them of food which results in a significant amount of weight loss (>5%) while a very large amount of clean water is needed. This is time-consuming and takes up to 15 days, but also water-consuming and costly, costing up to 5% of the revenue.

Ozone targets OFCs and may introduce a new way to avoid the purging of fish grown in RAS.

Add ozone to your Aquaculture

The geosmin challenge is one of the biggest challenges for land-based fish farming, and solving this would be a game changer for RAS. One effective way of eliminating the OFCs is to treat the water with ozone.

However, ozonated water in large-scale RAS and flow-through fish farms have had different challenges.

Historically ozone generators have been big and complicated and were placed far from the treatment site and lead to the fish tanks through long pipes. But ozone rapidly decomposes and turns to pure oxygen, losing its oxidative properties. This is beneficial for the water environment and biofilter, but when most of the ozone has been degraded to oxygen before even reaching its goal, it made the treatment ineffective and expensive in RAS.

This problem has been solved with the ozone generator Gaia, developed by Water ApS. Gaia is one of the most powerful and high-producing generators on the market. Gaia is a modular ozone generator separated into smaller units working separately. The modular prospects of the generator make it possible to place the generator directly at the treatment site and treat the water without any loss of ozone. This makes the ozonation process highly effective, and much cheaper in use.

Gaia works along with the OxyGuard equipment; the Pacific, a measuring, monitoring and control system and the Ozone Sensor, developed to detect even the smallest amount of residual ozone. Supervision and control of ozone are necessary. Ozone is toxic to the fish, if not fully degraded when it reaches the fish tanks. But there are several solutions to make it safe. UV radiation in conjunction with ozone will destroy the residual ozone. With Helios UV technology (from Water ApS) you can make the UV radiation a part of your set-up. Supervision and control are manageable from anywhere online with the digital farm management tool Cobália.

Paw Petersen, CEO at OxyGuard International thinks that ozone is an essential player – moving forward; “In our ever-evolving aquaculture industry, we need to sharpen our focus on the water quality in RAS. Here, an essential player emerges: ozone.

Despite its three-decade presence in RAS, ozone has now become more accessible. Today we can measure and control the ozonation process in the same way we have done with oxygen in the past 40 years.

This will revolutionize farm building designs, improve water quality standards, lower the water usage in individual RAS setups and ultimately it will help land-based fish farming to hit the target”.

Ozone treatment for Saltwater

Ozone chemistry in saltwater is more complex compared to that in freshwater, due to the higher concentrations of dissolved ions. Katerina Spiliotopoulou, Environmental Engineer at Water ApS explains: “Seawater naturally contains bromide ions (Br-) which are highly reactive to ozone. When ozonating seawater, bromide ion (Br−) is oxidized to hypobromite (OBr-), bromite (BrO2-) and eventually bromate (BrO3-) which are of crucial importance since they have long lifetimes allowing for several side reactions to occur. OBr- also reacts with ammonia and proteins to form bromamines. Both bromamines and hypobromous acid (HOBr) are toxic to fish, bivalves and crustaceans”. To ozonate safely salt water it is important to ensure the presence of organic matter. As long there is organic matter in the water ozone will react with it first as it is much easier to degrade than anything else.

OxyGuard solved this challenge with the fast-reacting ozone sensor that can measure ozone directly in the water in real time. By adding the ozone sensor to the system, it is possible to ozonate safely based on feedback from the sensor.

On top of this solution, OxyGuard developed a control feature for ozonation in the Pacific Control System, enabling automated control of the ozonation based on feedback from the sensor.

The system has been tested through different developmental projects such as RASALT, where OxyGuard, in collaboration with DTU, the Technical University of Denmark, worked with feedback from the ozone sensor and the ozone generator to avoid brominated by-product formation. The sensor and the generator were hooked up to the digital farm software, Cobália, and Cobália is now developing a module specifically for safe and efficient ozonation control. The aim is to automatically turn on and off the ozonation based on feedback from the water matrix. This add-on will increase security and efficiency, making it easy and cheap to use.

Optimizing the fish health

In ProBiOzon, another collaborative project between OxyGuard, DTU Aqua and primary producers, the effect of ozonation was tested on fish health and mortality in freshwater RAS. The results showed a general, overall improvement in fish health and following a lower mortality. It improves water quality by removing organic matter and it helps the biofilter function through the supply of pure oxygen for ozone degradation.

In a new project, Bizon, led by OxyGuard, the entire system will be tested full scale to see if ozonation could completely remove the need for purging or if it will only solve part of the challenge. The Bizon project concludes in 2026.

Is ozone a solution for you?

OxyGuard International and Water ApS have already implemented the system on several large RAS. It is installed as a part of the entire water cleaning setup on the farms, targeting a sub-stream of the recirculation water.

If the entire setup is effective enough to completely remove geosmin from the water, it will change the way we produce fish in RAS and the feasibility of RAS in general.

Your success is our goal - let us help you achieve it

Links:

Oxyguard: www.oxyguard.dk

Water ApS: www.water.dk

Cobália: www.cobalia.com

Projects:

RASALT: https://youtu.be/eI5p1U6Dd9E

ProBiOzon: https://orbit.dtu.dk/en/projects/improved-water-quality-by-means-of-protein-skimming-biofiltration

Equipment:

Gaia: https://www.water.dk/en/choose-uv-or-ozone/choose-ozone-product-below/gaia/

OxyGuard Pacific control System: https://www.oxyguard.dk/en/systems/pacific/#

OxyGuard Ozone Sensor Probe: https://www.oxyguard.dk/en/probes/oxyguard-ozone-sensor/

Helios UV Technology: https://www.water.dk/en/choose-uv-or-ozone/uv-water-treatment-solutions/

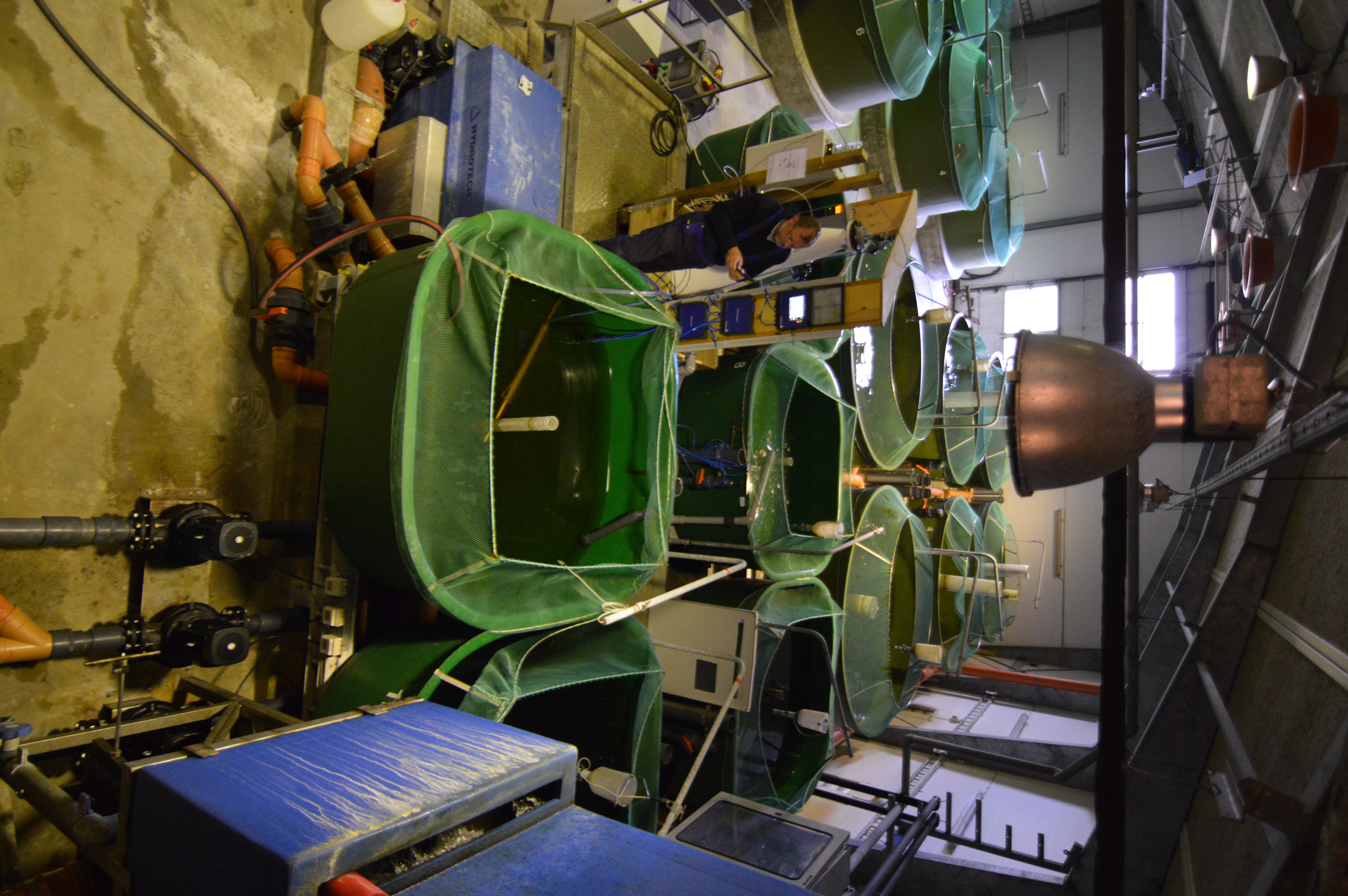

Figure: An example of a setup of the system, where all equipment is used for the optimal cleansing process

This article was published in the magazines International Aquafeed and RasTech Magazine:

https://issuu.com/international_aquafeed/docs/iaf2403_w1/48

https://mydigitalpublication.com/publication/?m=60230&i=817090&p=8&ver=html5